Your cart is currently empty!

Specifications

- Contacts Materials

- IeGO PUM 4N 99.99% Furukawa Pure Copper 24K Gold Plated

- Contact Dimensions

- Width: 6 mm, thickness: 2 mm

- Included Accessory

- 2 mounting screws, 3 Gold Plated contact screws, 3 Silver Plated copper ring terminals

- Treatment

- Cryo‐treatment at −196°C for 20 hours

- Rated Voltage

- 15A – 125V AC

- Housing Material

- Highest grade PC flame retardant GE 940A Polycarbonate

This product is made according to international standard IEC320 C14 size, provides for a conveniently direct installation into most standard cutouts.

Sound Characteristics

- The sound is transparent, soft, and warm

- The sound stage is wide and deep

- The bass is deep, articulated, and fast

- The midrange is very comfortable, smooth, and open

- Good details and resolution in all range

For maximum performance, prior to use allow longer burn‐in time.

Cryo‐treatment

All IeGO power connectors have continuous cryogenic treatment by liquid nitrogen (−196 °C) for 20 hours. Cryogenic processing changes their metal microstructure at the molecular level. The crystal structure becomes smoother and more refined. The conductivity of the metal improves, which positively affects the signal transmission, and as a result — the sound. Changes in the structure of metal after cryogenic treatment are permanent and do not change over time.

Connectors with cryogenic treatment sound much better than their counterparts.

99.99% Furukawa Pure Copper for contacts

Unlike most of the other manufacturers, whose production of connectors uses brass or phosphor bronze with much lower conductivity, IeGO Power Dream Works uses only pure copper with advanced treatment to achieve maximum results of sound quality.

The material for IeGO connectors is the premium "red copper - 1020" — 99,99% of purity from the famous and reputable Japanese company Furukawa. Products from this copper sound better, thanks to the smaller sizes of crystals, which critically affect the signal transmission and loss in them.

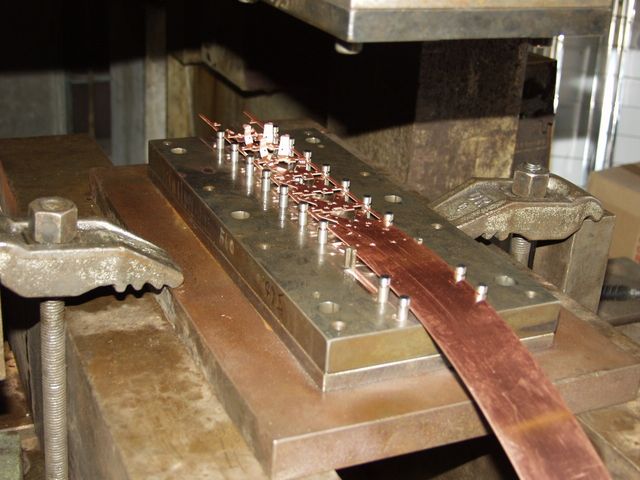

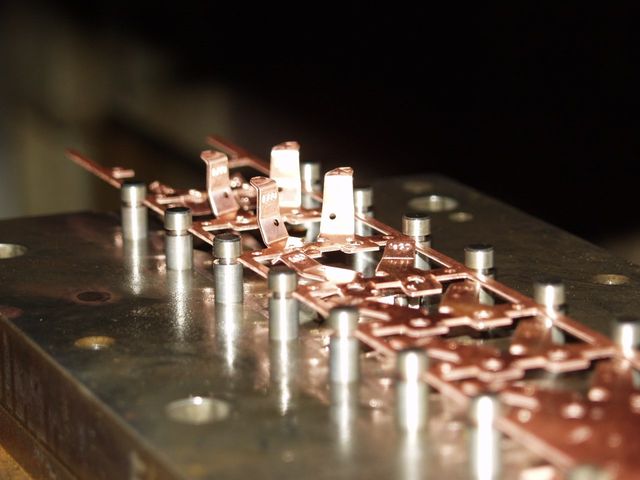

At the factory, the perforation of pure copper sheets is done by computer stamping. During the process, the oxides are completely removed by etching. It’s followed by a washing process that removes residual liquid nitrogen. Pure copper achieves high resilience and meets stringent electrotechnical standards. At the last stage of production, contacts get ground and then polished to a shiny surface. Depending on the connector model, contacts are covered with a layer of gold, silver, or rhodium. At last, the plated contacts are polished again.

Housing material and other parts

To maximize the quality of its products, IeGO also pays special attention to other parts of connectors — housing material and fixing screws. The case of power connectors is made of special highest‐grade PC flame retardant Polycarbonate 940A with high specific gravity. Developed by the Japanese company “General”, it complies with the specifications of the UL standard E-45587 and has shock resistance, UV resistance, fire resistance, and a high degree of absorption of micro‐vibrations. The dielectric is the best, the capacitive reactance and impedance can reach the optimal sound performance.

The design of contacts allows clamping a cable by the whole surface with the aid of a special square buckle made of hard pure copper. The clamping screws are made of non-magnetic stainless steel and are color-coded.

Do not attempt to install AC−01 yourself if you do not have any experience with AC power. If you are not sure about your skill, please ask an experienced professional to install it.

Recommendations for installing a Power Inlet

IeGO does not recommend soldering on AC−01 power inlets. As the thickness of pins is twice more standard and the thermal conductivity of contacts is extremely high, it is therefore very difficult to solder contacts without melting the plastic housing. This can lead to damage to housing geometry, and could potentially lead to damage to AC‐01 and/or your equipment.

For a safe installation of AC‐01, we recommend using the mounting accessory set, which is included in the package.