Your cart is currently empty!

Specifications

- Live & Neutral Contacts Material

- ETP Pure Copper non‐plated

- Ground Contact Material

- Brass

- 20A — 125V AC

- Housing Material

- Custom‐made A‐class flexibility, high impact, chemical resistant, and fire‐proof nylon

- Terminal Accommodation

- 10 — 14 AWG

- Dimensions

- 52 mm x 37 mm x 71.5 mm

- Packaging

- Pyrocondesation membrane wrapping and individual paper box

Design

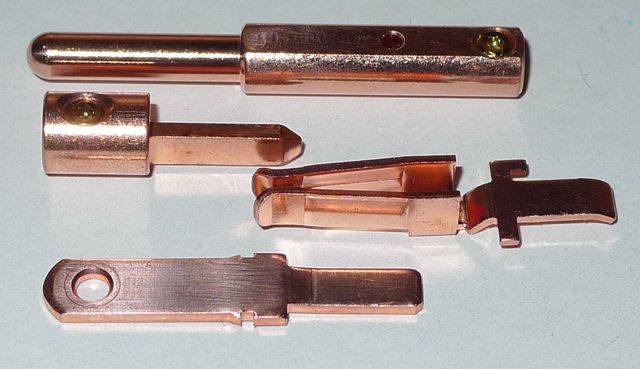

For American‐style receptacles (USA outlets) ATL company has developed and implemented its own contact design. Special five‐leaf clamp design allows to get a smoother and more stable contact with the enlarged contact surface, but at the same time has sufficient clamping force to not damage layer of the coating during repeated use. Perhaps this is the most ideal contact in terms of electrical and sound results.

The clamping screws are made of non‐magnetic stainless steel and brass and color‐coded: Live — brass, Neutral — white, and Ground — green.

ETP Pure Copper for contacts

ATL Power company uses custom‐made ETP pure copper (Electro Tough‐Pitch), also known as cathode electrolytic copper. This copper, purity of which is 99.99%, has conductivity of not less than 100% of IACS (SGS certified) and nearly zero current loss at its transmission. Most manufacturers use brass or phosphor bronze for the production of power connectors, whose electrical conductivity is very low. Brass has only 25‐30%, and phosphor bronze — about 13%.

Due to the very high conductivity of ETP copper, we have very low contact resistance, thanks to which the current flows smoothly and results in a dramatic improvement in sound performance on a power system. It gives a big advantage to ATL connectors in comparison with other brands!

ETP copper is also highly plastic and resilient. This copper has excellent electrical and heat conductivity, good anti‐corrosion, weatherproof properties, and also sufficient hardness for use in power connectors, thanks to special ATL treatment.

Housing material

ATL Power Plugs, IEC Connectors, Receptacles, and C7 Connectors housing is made of custom‐made A‐class flexibility and high impact/fire‐proof nylon material. It is not only for safety considerations in audio, but it is also helpful in terms of medium/low frequency performance. This is what ATL studied long‐term and made other materials through comparison and testing.

Different hardness of the material produces different sound. It was found that some harder materials make the sound more energetic, with the articulated bass, while softer materials influence on all range, making the sound more solid and smooth. All these features are balanced in ATL connectors.

ETP Pure Copper products are softer than brass due to their material characteristics. Care must be taken to slowly wiggle brass screws into copper contacts and brute force should not be used for this. It is very important that excessive force is not exerted onto the components.